Swiss screw machining is a production method employed for crafting precise parts in large volumes. Utilizing automatic lathes, known as Swiss screw machines, this process is programmable to fabricate an array of metal and plastic components with utmost accuracy. Operating round the clock, these machines bolster production rates while curbing expenses.

At MaTec Vietnam, our factory comprises diverse precision machining tools and screw machines, encompassing CNC Swiss screw machines and multi-spindle variants. Each machine type offers distinct capabilities and advantages.

Renowned for its ability to churn out sizable quantities of components with exceptional precision, repeatability, and adherence to tight tolerances, Swiss screw machining epitomizes manufacturing excellence.

In this article, we delve into the capabilities, advantages, and all you need to grasp about Swiss screw machining.

What is Swiss Screw Machining

Swiss screw machining, also known as Swiss turning or Swiss automatic machining, is a highly efficient manufacturing process designed for the production of precision parts in large quantities. Originating in the late 1800s, Swiss screw machines, named after their birthplace in Switzerland, were initially developed to mass-produce screws and small precision components, particularly for the watchmaking industry.

Over time, Swiss screw machines evolved and expanded their capabilities beyond screw production. By the 1960s, they had gained significant traction globally, becoming indispensable in various industries. Today, Swiss screw machining is utilized worldwide to manufacture millions of intricate metal and non-metal components with unparalleled accuracy and efficiency.

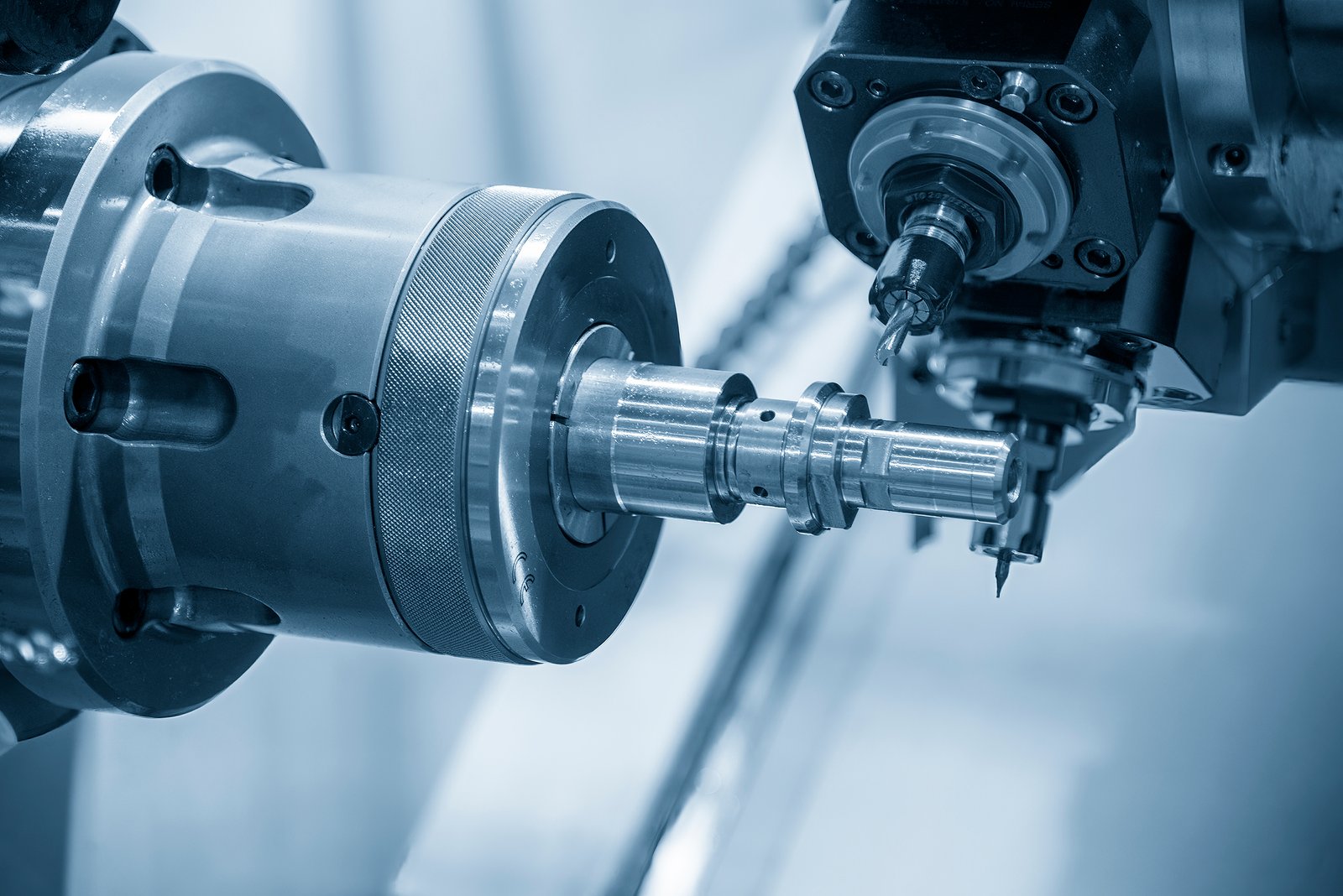

These automatic lathes, programmable to produce a wide range of precision parts, operate tirelessly, running 24/7 to enhance production speed and reduce costs. Their versatility and ability to maintain tight tolerances make them ideal for crafting complex components with exceptional precision.

In essence, Swiss screw machining represents the pinnacle of manufacturing excellence, enabling the production of high-quality parts with remarkable efficiency and consistency.

Advantages of Swiss Screw Machining

Advantages abound with Swiss screw machining, making it a top choice for manufacturers requiring precision parts in bulk. This advanced manufacturing method offers heightened efficiency, material versatility, and design flexibility compared to other machining techniques. Here’s a breakdown of why Swiss screw machining could be your next project’s optimal solution.

Enhanced Efficiency

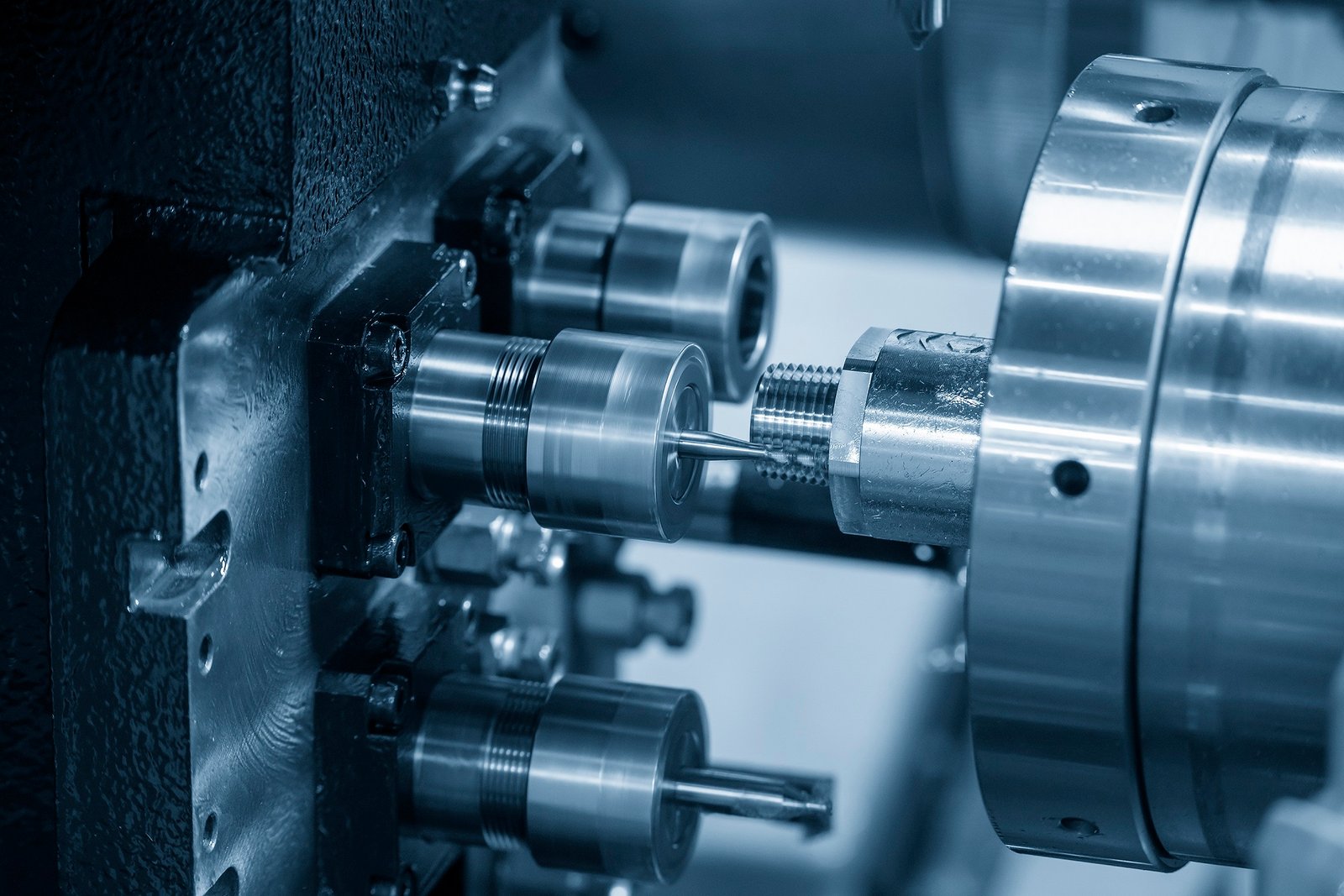

Swiss screw machines excel at multitasking, enabling simultaneous work on multiple parts, particularly advantageous for high-volume orders. Multi-spindle Swiss screw machines take this a step further, performing various cuts, slotting, and drilling concurrently. With each spindle equipped with a unique cutting tool, parts are efficiently formed without the need for additional machining, significantly boosting production speed.

For instance, a typical multi-spindle machine with 6 main spindles can machine 6 parts in the time it takes to machine one part conventionally. Additionally, once programmed, these machines can operate continuously for extended periods, minimizing the need for manual intervention and expediting large-scale projects.

Lower Manufacturing Costs

The efficiency of Swiss screw machines translates to reduced labor hours and enhanced cost-effectiveness, particularly for high-volume production runs. While not ideal for prototype production, this method significantly lowers costs when thousands of identical parts are required. Industries such as automotive, aerospace, defense, and medical benefit from these savings, ultimately passed on to consumers.

Reduced Waste

Swiss screw machining’s precision capabilities minimize errors and unusable parts, thus reducing waste. By performing multiple functions simultaneously, these machines further decrease labor hours spent on production. Additionally, scrap metal generated during the process is collected and recycled, contributing to sustainability efforts.

Material and Design Diversity

Swiss screw machines accommodate a wide range of materials, including various grades of metal, polycarbonates, and plastics, with exceptional precision. This versatility allows for the selection of materials tailored to specific project requirements, even those traditionally challenging to machine, such as Hastelloy and stainless steel.

Moreover, advancements in design capabilities enable the creation of intricate components previously deemed too costly or impractical for conventional machining techniques. Engineers and designers can explore diverse design options to enhance performance and cost-efficiency, creating components for applications across industries like automotive, aerospace, and medical.

High Precision

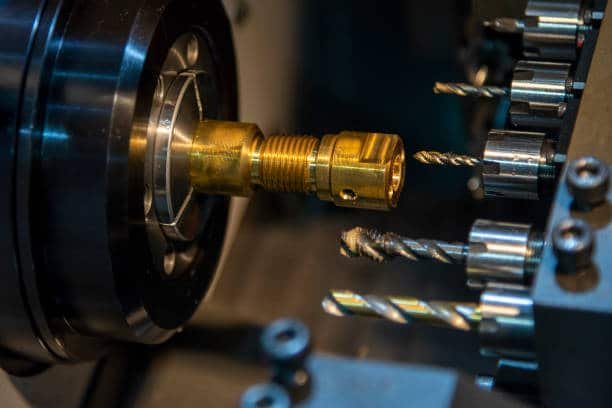

Swiss screw machines boast unparalleled precision, thanks to robust support provided by guide bushings. This stability ensures precise cuts and drills, even for smaller parts prone to vibration during machining. Furthermore, the machining process can achieve surface finishing, eliminating the need for secondary operations.

With the ability to spin parts at high speeds and maintain tight tolerances as low as ±0.005mm (0.0002in), Swiss screw machining surpasses turret machines in precision, thanks to sophisticated CNC controllers that continually adjust and correct tooling operations during operation.

How are Swiss screw machines operated?

How Swiss screw machines operate is a fascinating process. It all begins with programming the machine using CNC controls, where the exact specifications of the part are inputted. This guides the machine on how to precisely cut and drill the raw material to shape the desired component.

Following the programming stage, raw metal, typically in the form of bar stock, is loaded into a bar feeder. This feeder contains a substantial amount of bar stock, enabling continuous operation for extended periods, facilitating the swift completion of high-volume orders with minimal human intervention.

The bar feeder then feeds the rotating round bar through a collet, which securely holds the material in place as various features are machined. As the spinning chuck seizes the raw material, it extends it out to the specified part length. Subsequently, the collet clamps onto the part, securing it while machining takes place.

A guide bushing is employed to minimize the gap between the main spindle and the cutting tools, ensuring precise machining.

Once the machining of a part is complete, it is severed from the bar stock, and the bar feeder advances the material to commence the machining process for the next part. This seamless and efficient operation exemplifies the precision and productivity inherent in Swiss screw machining.

Industries that Swiss screw machined can serve

Industries reliant on vast quantities of small precision parts find Swiss screw machining indispensable for their manufacturing needs.

At MaTec Vietnam, our Swiss screw machines are instrumental in producing a diverse array of high-quality components, including spacers, pins, housings, screws, connectors, and sleeves. These meticulously crafted parts serve a multitude of industries, including automotive, medical, defense, and aerospace.

The precision and efficiency of Swiss screw machining are integral to maintaining robust supply chain management for our clients, enabling the creation of cutting-edge consumer products across various sectors.

Read more: What is Swiss Machining? Benefits of Swiss Machining

Conclusion

This comprehensive guide has provided a thorough understanding of Swiss screw machining, covering its principles, applications, and advantages.

From its inception to its modern-day significance in precision manufacturing, Swiss screw machining remains a vital technique for producing high-quality components with unparalleled accuracy.

As you embark on your journey to explore the world of Swiss screw machining, MaTec Vietnam stands ready to support your needs.

With our expertise, state-of-the-art facilities, and commitment to excellence, we offer reliable Swiss screw machining services tailored to meet your specific requirements. Contact MaTec Vietnam today to discover how we can help you achieve precision and excellence in your machining projects.