Swiss Turning Shop, originating from the watchmaking industry, is a highly precise manufacturing technique utilizing specialized lathes and cutting tools to create intricate parts with exceptional accuracy.

Its ability to handle complex geometries and tight tolerances makes it a preferred choice for industries requiring precision components. In this article, we’ll explore the essence of Swiss machining and its myriad benefits for modern manufacturing.

What is Swiss Turning

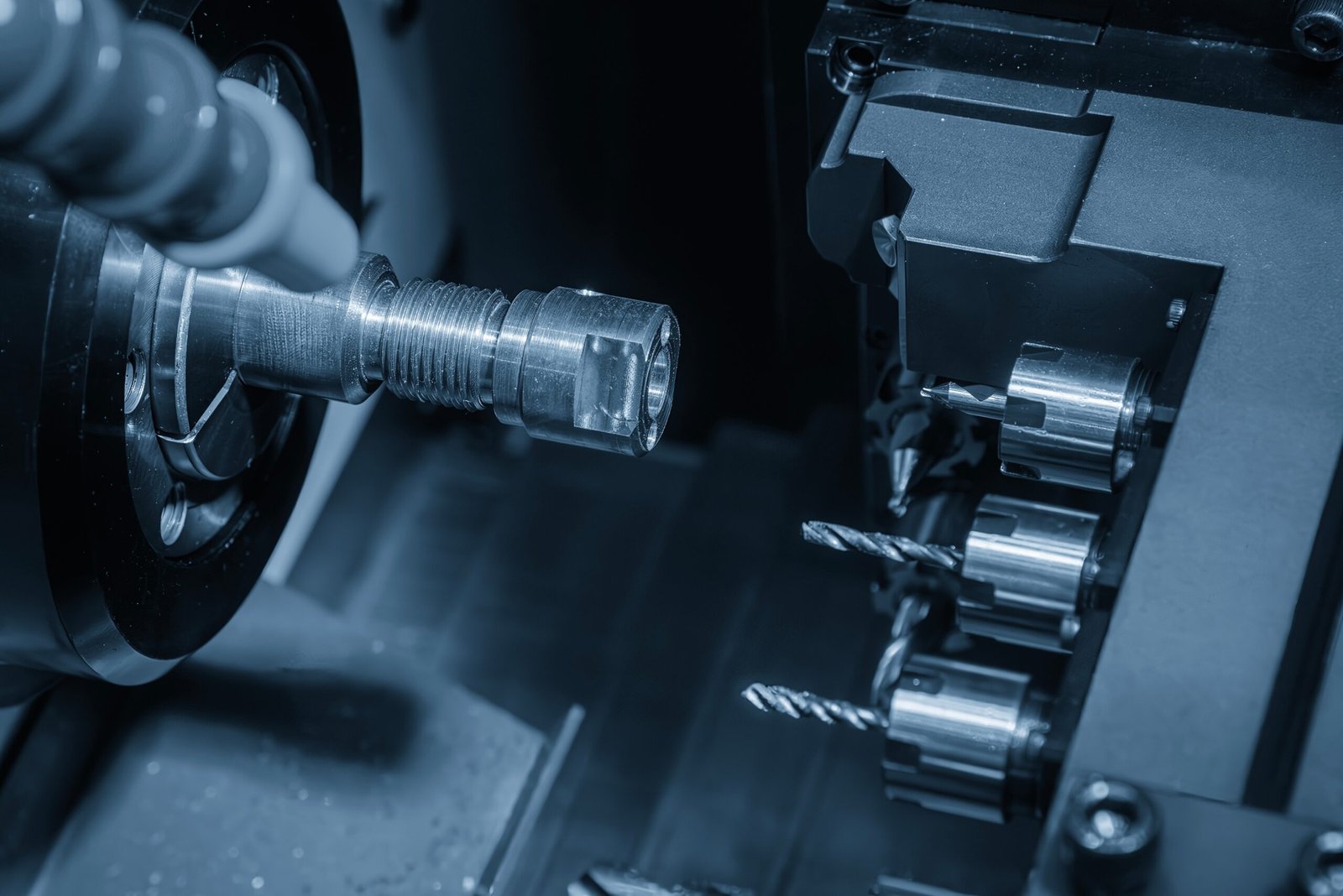

Swiss turning, also known as Swiss-style turning or Swiss-type machining, is a specialized manufacturing technique renowned for its ability to produce intricate, slender, and complex parts with exceptionally tight tolerances.

At its core, Swiss machining involves the use of a CNC-operated lathe that employs a unique radial cutting motion to shape metal stock into finished components.

The distinguishing feature of Swiss machining is the design of the lathe, which holds the workpiece securely in place while rotating it precisely. Unlike conventional lathes where the workpiece rotates against the cutting tool, in Swiss machining, the cutting tool moves in a radial motion relative to the stationary workpiece.

This setup allows for greater stability and control during the machining process, particularly when working with small-diameter parts.

Where Does Swiss Turning Come From?

The origins of Swiss machining can be traced back to the watchmaking industry, where the demand for increasingly smaller and more precise components necessitated innovative machining solutions.

Swiss watchmakers, faced with the challenge of crafting intricate parts with utmost precision, developed the initial concepts of Swiss-style lathes. These early machines were designed to minimize flexing and vibration, ensuring the accurate machining of tiny components.

Over time, Swiss machining has evolved to encompass a wide range of industries beyond watchmaking. Today, it is widely used in sectors such as automotive, medical, aerospace, electronics, and defense, where the demand for high-precision components is paramount.

>>> Read more: What is Precision Machining? Advantages and Disadvantages of Precision Machining

Where Is Swiss Machining Utilized?

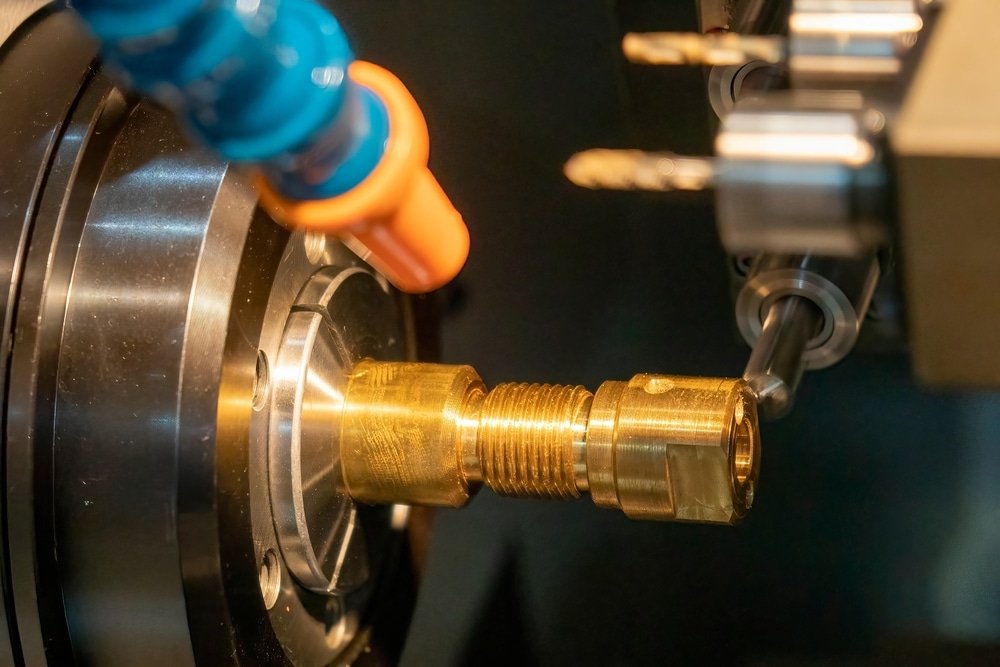

Swiss machining finds its application in various industries, primarily automotive, medical, defense, and electronics. It excels in producing small, intricate parts in high volumes.

These parts serve diverse purposes, including medical devices, optical equipment, firing pins, shafts, timepieces, and connecting components for electronic devices and aerospace parts.

CNC Swiss-style machining specializes in manufacturing longer, slender, and complex parts with exceptional precision, efficiency, and throughput. In the medical sector, where exacting standards are crucial for surgical screws and tools, Swiss machining shines.

However, its benefits extend beyond medical applications. Industries like aerospace, computers, electronics, energy, precision timing, and defense systems rely on Swiss machining for various components such as implants, shafts, contact pins, housings, inserts, and sockets.

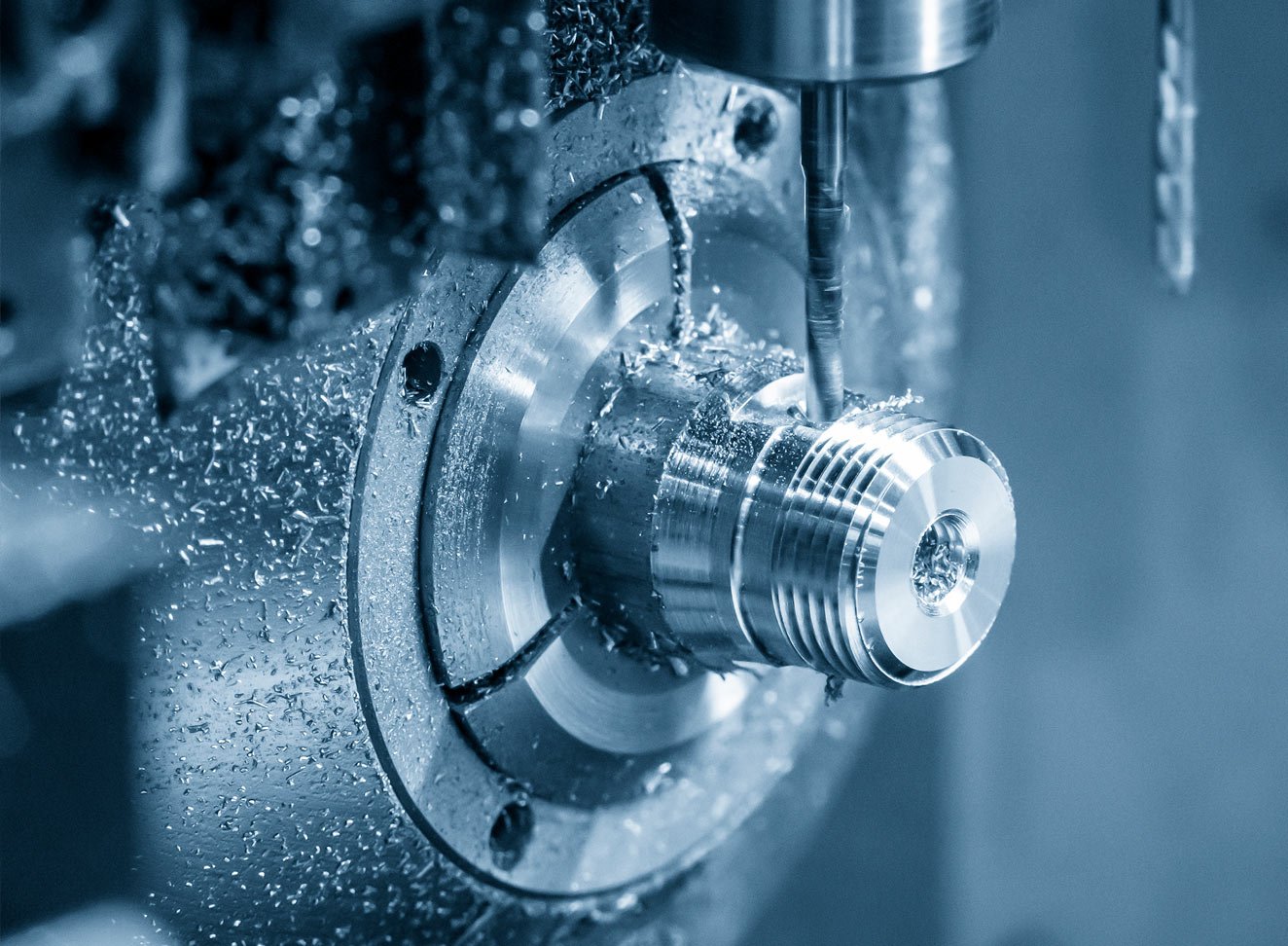

Swiss CNC machining offers extensive capabilities, catering to small runs of a few hundred pieces to large-scale production exceeding hundreds of thousands. It seamlessly integrates multiple processes like milling, threading, drilling, boring, turning, and custom requirements.

With Swiss CNC machining, designers gain enhanced control over complex part production, as one machine can execute several operations concurrently, reducing production time.

The precision of Swiss CNC machining allows for the fabrication of intricate stainless steel parts ranging from 0.030 inches to 2 inches in diameter, meeting the stringent specifications of diverse applications. Moreover, metals like Inconel, titanium, nickel, and nickel-based alloys can also be utilized to achieve close tolerances within 0.0001 inches concentricity to ±0.0005.

Swiss machining excels in micro-machining tiny components with unmatched accuracy, making them stronger, smaller, and lighter at a faster pace. Consequently, Swiss machines surpass other CNC machining systems in handling complex machining operations effectively.

Benefits of Swiss Turning

- Tight Tolerances: Swiss machines excel at maintaining extremely tight tolerances, even for small and intricate parts. The workpiece is firmly supported throughout the machining process, minimizing deflection and ensuring precise dimensional accuracy.

- Complex Part Geometry: Swiss machining enables the production of parts with complex geometries, thin walls, and intricate features that would be challenging to achieve with conventional machining methods. The radial cutting motion allows for deeper cuts and delicate machining operations.

- High Efficiency: Swiss machines are known for their efficiency and high production rates. With shorter cycle times compared to traditional CNC machines, they can produce a large volume of parts in a relatively short time frame, making them ideal for high-volume manufacturing.

- Ready-to-Ship Parts: The precision and accuracy of Swiss machining often result in parts that require minimal or no additional finishing operations. This streamlines the manufacturing process and reduces lead times, as parts can be produced and shipped directly from the machine.

MaTec Vietnam – Your Reliable Manufacturing Partner

At MaTec Vietnam, precision and reliability are not just promises but principles we live by. Specializing in Swiss machining, we have honed our craft to offer clients nothing short of perfection.

Our cutting-edge Swiss machines, complemented by the expertise of our seasoned technicians, ensure that each component surpasses the highest standards of quality and accuracy.

With a commitment to innovation and unwavering dedication to customer satisfaction, MaTec Vietnam stands as a beacon of excellence in the machining industry. Our track record speaks for itself, with over 45 engineering projects successfully executed and more than 50 industry partners trusting us for their machining needs.

Behind our success are the skilled hands and sharp minds of our team, comprised of over 10 machinists and engineers who bring passion and proficiency to every project. Together, we continue to push boundaries and redefine what is possible in the realm of sophisticated machining solutions.

Conclusion

Swiss machining stands as a testament to the ingenuity and precision of modern manufacturing techniques. Its origins in watchmaking have evolved into a versatile method capable of producing intricate parts with unmatched accuracy.

The benefits of Swiss machining, including superior precision, efficiency, and versatility, make it an indispensable tool for industries seeking optimal results in precision manufacturing.

As technology continues to advance, Swiss machining will undoubtedly remain at the forefront, driving innovation and excellence in the manufacturing landscape.