Top 10 Precision Machining Services Companies In Asia

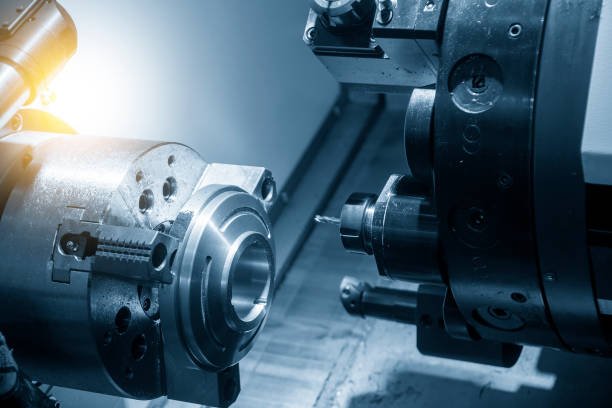

In the dynamic world of manufacturing, Asia stands as a powerhouse, boasting a myriad of Precision Machining manufacturers that set global standards for precision, quality, and innovation. From the bustling industrial hubs of Vietnam to the technological forefront of Japan and China, the region is home to a diverse array of companies leading the charge in Precision Machining.

In this exploration of excellence, we uncover the top 10 Precision Machining Services Companies in Asia, each wielding expertise and ingenuity to shape industries and redefine the boundaries of possibility in modern engineering. Join us as we journey through the innovative landscapes of Asia’s manufacturing giants, where precision meets passion and craftsmanship knows no bounds.

| Company Name | Year Founded | Country | Employee Size |

| MATEC Vietnam | 2015 | Vietnam | 11-50 |

| AT Machining | 2010 | China | 21-50 |

| 3ERP | 2010 | China | 11-50 |

| DEK | 2002 | China | 51-200 |

| Wayken | 2002 | China | 51-200 |

| TDB Hanoi | 2015 | Vietnam | 11-50 |

| Junying | 2005 | China | 51-100 |

| Runsom Precision | 2005 | China | 11-50 |

| Tik Precision | 2018 | China | 200-500 |

| HLH | 2002 | China | 51-200 |

1. MaTec Vietnam

MATEC Vietnam emerges as a distinguished addition to the esteemed MATEC family, renowned globally for its dedication to precision engineering and Precision Machining excellence. Reflecting the core values of quality, innovation, and customer-centricity, MATEC Vietnam stands out as a premier destination for tailored Precision solutions in Southeast Asia.

Leveraging the extensive expertise and legacy of the MATEC brand, MATEC Vietnam offers a comprehensive suite of Precision services meticulously designed to meet the diverse needs of industries spanning aerospace, automotive, medical, and beyond. Their cutting-edge facility in Vietnam is equipped with advanced Precision Machining, turning, and milling equipment, enabling them to handle projects of any scale and complexity with unparalleled precision and efficiency.

At MATEC Vietnam, precision and quality are paramount. With a team of skilled engineers and machinists, they uphold the highest standards of craftsmanship, ensuring that each component produced meets stringent specifications and surpasses expectations. Their ISO 9001 certification underscores their commitment to quality management systems, ensuring consistency and excellence in every project.

Driven by innovation, MATEC Vietnam continuously invests in the latest Precision technology and training to stay ahead of the curve. This dedication to innovation allows them to offer customized solutions to clients, from specialized finishes to intricate geometries and rapid prototyping, all while optimizing production processes for cost-effectiveness and efficiency.

With a customer-centric approach, MATEC Vietnam builds lasting partnerships based on trust, reliability, and transparency. They collaborate closely with each client, understanding their unique challenges and objectives to tailor manufacturing strategies that align with their vision and requirements.

Their track record includes successfully completing over 45 engineering projects and establishing partnerships with over 50 industry leaders who rely on them for their Precision Machining needs.

With a team of over 10 machinists and engineers, MATEC Vietnam ensures seamless execution and timely delivery of projects, regardless of complexity. While their reach extends globally, their commitment to local service remains steadfast, providing personalized attention and logistical support to meet the needs of the Vietnamese market and beyond.

2. AT Machining

Established in 2010 in Shenzhen, China, AT Machining specializes in rapid prototyping and Machining services tailored for short to medium production runs. Committed to delivering fast turnaround times and precision, the company prides itself on achieving tolerances as tight as ±0.005mm.

With over a decade of manufacturing expertise, AT Machining has cultivated partnerships with over 420 customers globally, resulting in the custom Machining of more than 2 million parts. Offering a diverse selection of over 100 materials, the company caters to industries including medical, robotics, green energy, and industrial sectors. Ensuring quality through ISO 9001:2015, SGS, and RoHS certifications, along with material authenticity, underscores its dedication to high precision and rapid production turnarounds.

Advantages of collaborating with AT Machining:

- Precision achieved through 3-, 4-, and 5-axis Precision Machining.

- Comprehensive surface finishing options available.

- Maintenance of tight tolerances for metals and plastics.

- Support for both low volume and mass production requirements.

- Cost reduction by 30-50% through efficient production practices.

- Reliable and expedited delivery services.

- Customized services offered for over 50 materials to meet specific project needs.

3. 3ERP

Established in 2010 in China, 3ERP specializes in rapid prototyping and low-volume manufacturing, aiming to expedite market entry for its clients. The company demonstrates adaptability to design changes and offers numerous options for bridge production, facilitated by its automated machinery ensuring swift and precise measurements.

Adhering to strict ISO quality standards, 3ERP has successfully completed over 30,000 projects, earning recognition for its precision and accuracy, with a manufacturing network capable of handling up to 10,000 units for end-use applications, showcasing its extensive manufacturing capabilities.

Advantages of partnering with 3ERP for Precision Machining Services are abundant:

- Tolerances as tight as ±0.01 mm.

- Monthly output exceeding 10K Precision parts.

- Thorough inspection of precision parts.

- Utilization of advanced in-house manufacturing and testing equipment.

- Specialization in tight tolerance Precision parts.

- Fast project turnaround guaranteed.

- Offerings of various high-quality surface finishes.

- DFM optimization provided by experienced engineers.

4. DEK

Founded in 2002 in China, DEK provides efficient and prompt manufacturing services to a vast clientele of over 2300 global customers. With a repertoire of diverse processing capabilities and advanced testing equipment, DEK specializes in crafting high-precision parts for intricate or tightly-toleranced products.

Proficient in Precision Turning, Milling, Sinker EDM, and more, DEK ensures unparalleled speed in delivering metal or plastic products, with the added benefit of no minimum order quantity, thus delivering cost-effective solutions to its clientele.

Advantages of DEK’s Precision Machining Services include:

- ISO Certification, ensuring stringent quality standards and reliability.

- Production track record exceeding 72 million parts, showcasing extensive experience.

- Over 21 years of manufacturing expertise.

- Capability to manage production volumes ranging from low to high.

- Provision of both vertical and horizontal Machining services, accommodating diverse project requirements.

5. Wayken

Based in Shenzhen, China, Wayken distinguishes itself with over two decades of expertise in the manufacturing sector, supported by a team exceeding 60 seasoned professionals. As specialists in Precision Machining, Rapid Tooling, 3D Printing, and Clear Prototyping, the company boasts cutting-edge machinery ensuring a product pass rate exceeding 95%. With a steadfast dedication to exceptional customer service, Wayken pledges individualized support with response times within 12 hours.

Partnering with Wayken for Precision Machining services yields numerous advantages:

- Accommodating both small and large production volumes.

- Providing quotes for over 30 types of engineering-grade materials within a 12-hour timeframe.

- Swiftly offering Design for Manufacturing (DFM) feedback to ensure project success.

- Achieving tight tolerances up to ±0.05mm and surface smoothness of Ra0.2μm.

- Promising industry-leading turnaround times for projects.

- Adhering to ISO 9001:2015 standards, with an unwavering commitment to 100% part inspection.

- Engaging in direct, one-on-one collaboration for enhanced project oversight and DFM guidance.

6. TDB Hanoi

TDB Hanoi Co., Ltd. is recognized as a trusted provider of precision Machining solutions, delivering a comprehensive range of Machining services to meet diverse industry requirements.

Established in 2015, TDB Hanoi has positioned itself as a leading multi-axis Precision Machining manufacturer in Vietnam, adhering to stringent quality standards across all operations. With a robust infrastructure comprising over 50 Precision machines and an extensive inventory of more than 100 metal materials, the company ensures timely manufacturing and delivery of parts with unparalleled reliability.

Since 2016, TDB Hanoi has expanded its capabilities to include prototype and OEM parts manufacturing using Precision machines, further enhancing its expertise in Precision Machining, Swiss Precision Machining, Finishing, and Assembly.

MISSION STATEMENT

Driven by a commitment to excellence, TDB Hanoi aims to attain global recognition for its technical prowess and total value solutions. The company endeavors to surpass the expectations of customers, employees, and the community, fostering a culture of zero complaints.

CLIENTS AND EMPLOYEES

TDB Hanoi is dedicated to providing globally competitive total value solutions by harnessing cutting-edge technologies. Moreover, the company prioritizes the professional growth, security, and competitive benefits of its employees, ensuring they have the requisite skills and opportunities for career advancement.

7. Junying

Junying Manufacturing stands as a prominent provider of custom online Precision Machining services in China, leveraging over 15 years of expertise in industrial parts production and product design. Since its establishment in 2005 in Dongguan, Junying has been dedicated to meeting diverse industry needs.

Junying’s Precision Machining services play a pivotal role in materializing design concepts across a spectrum of industries, including automotive, medical, military, aerospace, and more. The company boasts specialized teams proficient in Precision designs at various production stages, supported by skilled designers well-versed in a range of Precision software packages. This ensures the maintenance of quality for custom-machined parts while offering competitive pricing.

Key services offered by Junying include product design services, rapid prototyping, 3D printing, and industrial design services. Among the company’s advantages are:

- Large-scale manufacturing capabilities

- Expert technicians

- Reliable and high-quality Precision designs

- Speedy production and punctual delivery

8. Runsom Precision

Established in 2005, Runsom Precision specializes in Precision Machining, boasting extensive experience in the production of complex, high-quality parts. With a commitment to efficiency, the company adeptly handles both small and large orders while adhering to ISO standards to serve various industries. Runsom has successfully delivered over 2 million parts crafted from 90+ materials, ensuring product optimization through rigorous testing and evaluation processes. The team guarantees capability, punctuality, and expert support, achieving precise tolerances of ±0.0005 inches and ±0.01 millimeters to produce top-quality parts. Strict quality controls and ISO 9001 certification uphold the company’s standards.

Partnering with Runsom offers the following advantages:

- Accommodation of both low and high-volume production needs.

- Achievement of tight tolerances up to ±0.02 millimeters.

- Adherence to standard tolerances for metals and plastics.

- Quality assurance provided by expert QA teams.

- Fulfillment of high-standard component requirements.

- Provision of comprehensive 3, 4, and 5-axis Precision services.

- Support for a full series of materials.

9. Tik Precision

Established in 2018 in China, Tik Precision prioritizes a rigorous quality management system, specializing in high-precision Machining and rapid prototyping. With a focus on low-volume production and swift turnaround times, prototypes are processed within a week, accompanied by comprehensive reports.

The company pledges responses within 2 hours and supports various shipping options, ranging from 3 to 14 days. With the trust of over 3000 clients, Tik Precision operates from an ISO 9001 certified facility, ensuring top-notch quality across fast prototyping and mass production, excelling in coordination across multiple industries.

Advantages in Precision Machining Services:

- Rapid quotation and Design for Manufacturability (DFM) analysis.

- Utilization of advanced manufacturing and testing equipment.

- Swift turnaround for prototypes.

- Operation of over 100 advanced Precision machines.

- Specialization in low-volume custom Machining.

- Work with over 100 metals and plastics.

- Provision of authentic material reports and diverse surface finishes.

10. HLH

HLH Prototypes has earned a reputation for delivering exemplary services and products, effectively reducing production costs and time for businesses through its exceptional manufacturing capabilities. With a team of experts proficient in various Machining services, HLH Prototypes stands out for its commitment to excellence.

The company’s custom prototyping services are renowned for enhancing the quality and market value of products, offering highly flexible project solutions tailored to specific requirements. HLH Prototypes accelerates product delivery, ultimately boosting the bottom line of its clients, all while maintaining clear and constructive communication throughout the process.

Among its array of services including Precision Machining, rapid prototyping, injection molding, 3D printing, and sheet metal work, HLH Prototypes offers several advantages, including:

- Flexible and computer-aided manufacturing processes.

- Timely and efficient production schedules.

- Delivery of high-quality products meeting stringent standards.

- Competitive pricing ensures cost-effectiveness for clients.

Benefits Of Choosing Precision Machining Services Companies In Asia

Opting for Precision Machining services from Asia comes with significant advantages. Here’s a breakdown:

- Advanced Technologies: Companies in Asia invest in cutting-edge Precision technologies, prioritizing innovation to ensure unmatched precision and production efficiency.

- Cost Efficiency: Asia’s competitive cost structure offers affordability, facilitating cost-effective Precision Machining without compromising quality.

- Supply Chain Excellence: Asia boasts sophisticated logistics and supply networks that support seamless production flows, ensuring the efficient delivery of complex Precision projects.

- Diverse Market: The vast manufacturing landscape in Asia provides unparalleled customization options. Clients benefit from a wide selection of materials and Machining capabilities.

- Skilled Labor: Asia boasts an abundant workforce of highly trained Precision specialists, driving Machining excellence. Their expertise guarantees top-tier quality and innovation in Precision Machining.

These collective benefits make Asian Precision Machining services a wise choice for those seeking efficiency, quality, and value.

>>> Read more: Advantages of CNC Machining in Vietnam: Cost-Effectiveness, Skilled Workforce, and Advanced Infrastructure

How To Choose The Right Precision Machining Services Shop in Asia?

Selecting the perfect Precision Machining shop in Asia requires focusing on several key factors to ensure the success of your project:

- Experience Matters: Assess the shop’s operational tenure to gauge its proven track record and industry expertise.

- Certifications are Key: Look for shops with ISO 9001 and other relevant certifications, indicating a commitment to upholding global quality standards.

- Rigorous Quality Control: Investigate the shop’s quality control measures to ensure precision and durability in machined parts.

- Effective Communication: Evaluate communication efficiency and language capabilities for seamless interaction and accurate execution of project specifications.

- Comprehensive Production Capabilities: Verify the shop’s production capacity and technological prowess, as adequate resources and modern equipment are crucial for meeting diverse manufacturing demands.

Conclusion

When selecting the right precision machining services companies for your needs, it’s crucial to consider factors such as experience, certifications, quality control measures, communication efficiency, and production capabilities. By thoroughly evaluating these aspects, you can ensure a successful partnership that meets your requirements for precision, reliability, and efficiency.

For those seeking exceptional precision Machining solutions in Asia, MATEC Vietnam stands out as a premier choice. With its dedication to excellence, state-of-the-art technology, skilled workforce, and stringent quality standards, MATEC Vietnam offers unparalleled precision engineering services tailored to meet diverse industry needs.

From Precision Machining to rapid prototyping and beyond, MATEC Vietnam delivers top-tier solutions with efficiency, reliability, and a customer-centric approach. Choose MATEC Vietnam for precision Machining excellence that exceeds expectations and drives your business forward.