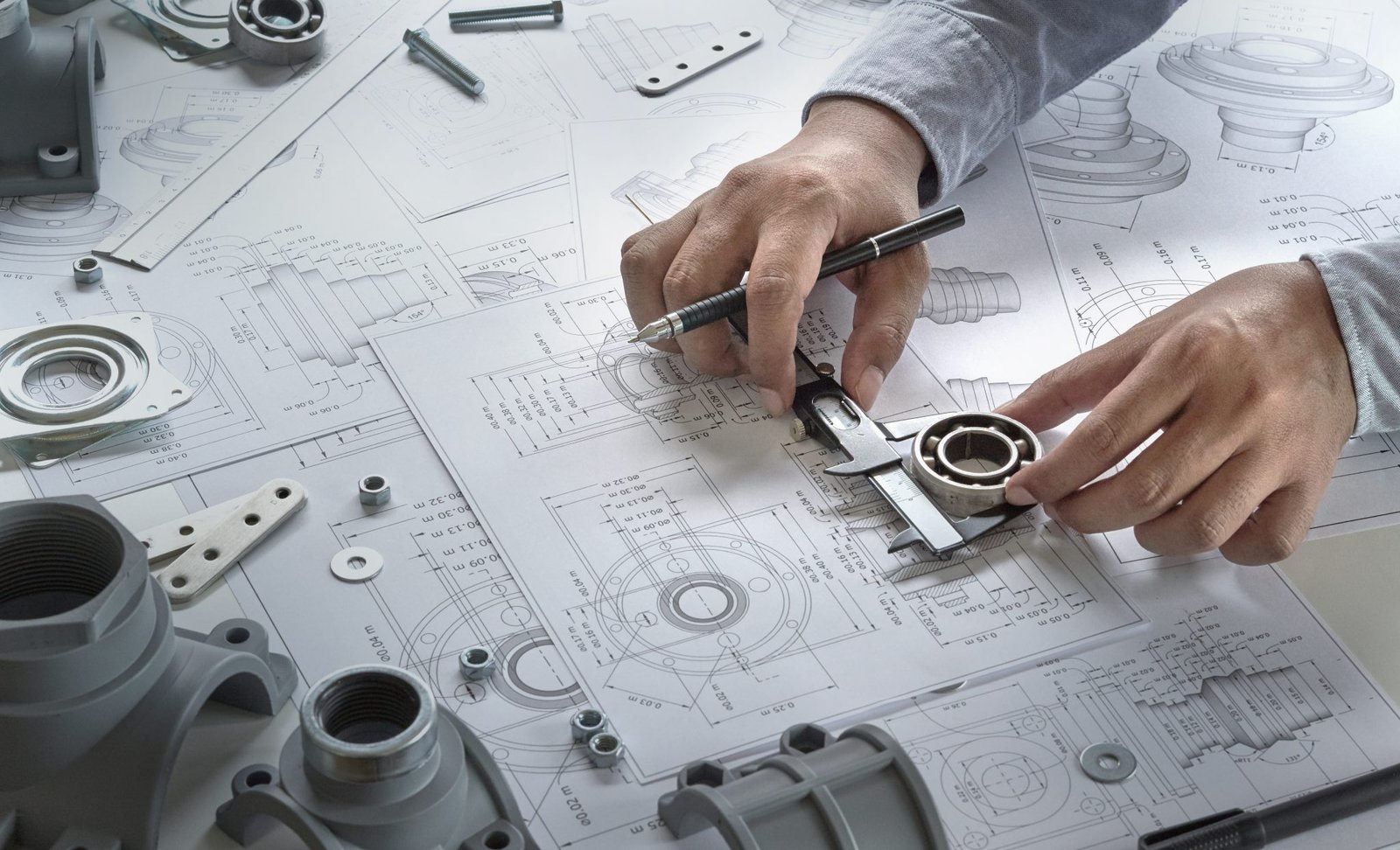

In today’s fast-paced manufacturing landscape, the significance of selecting the right CNC machining service provider cannot be overstated. With precision, efficiency, and quality at the forefront of production requirements, businesses face critical decisions when choosing a partner for their machining needs.

Whether it’s for prototyping or large-scale production runs, the choice of CNC machining service provider can profoundly impact the outcome of a project. Therefore, exploring key considerations in this selection process is imperative for ensuring optimal results and long-term success.

What Services Are Provided by CNC Machining Providers?

CNC machining service providers offer a range of machining services, including Swiss machining,CNC milling, and CNC turning. Moreover, they excel in managing all technical aspects of prototype part creation, leveraging their technical expertise and skilled team. This capability allows you to concentrate fully on bringing your product to market, knowing that the intricacies of prototyping are in capable hands.

Factors to Consider When Choosing a CNC Machining Service Provider

Assessing the Equipment Offered

When seeking a CNC machining service, it’s essential to evaluate the machinery and technology they offer. This holds significant importance for several reasons.

Firstly, engaging with a company equipped with only three-axis machinery is futile if your project necessitates five-axis CNC machining.

Instead, ensure the service possesses the requisite production equipment by reviewing their machine inventory, typically accessible online.

Secondly, ascertain the number of machining systems operated by the precision machining firm. This is especially important when there’s not much time to spare.

A smaller enterprise with only a couple of machines may require more time to achieve comparable turnaround times for parts compared to a larger entity with numerous machines in operation.

For example, at MATEC VIETNAM, we take pride in our extensive CNC machining capabilities supported by over 30 units of 3 and 4-axis CNC machines, alongside auxiliary and support machinery.

Examine and confirm certifications

This advice holds significant value in assessing the establishment and credibility of a precision machining facility, though its importance varies depending on the application.

For instance, selecting the right machine shop is paramount when producing parts for aerospace applications.

Furthermore, it’s imperative to ensure that the production facility holds the necessary accreditations for highly regulated sectors.

If your order pertains to medical equipment or components, it’s essential for the production partner to possess top-tier facilities and certifications.

Aside from these specific requirements, it’s advisable to be vigilant for other certifications, such as environmental credentials, supplier documentation, and quality assurance certifications.

At MATEC VIETNAM, we operate an ISO 9001 QMS-certified facility and adhere to ISO 9001:2015 standards.

Upon request, we also furnish quality assurance reports and material certifications.

Take into Account the Company’s Experience

Prioritizing experience is the initial recommendation when choosing the ideal precision machining facility. In essence, look for a company partner with a wealth of experience.

While there are newer, capable precision machining services emerging, those with extensive industrial experience—accumulated over time—tend to be reliable and proficient.

A seasoned manufacturing service possesses in-depth knowledge of production processes and maintains a reputation for client satisfaction and product delivery.

With over a decade of experience, MATEC VIETNAM manufacturing service has supplied parts to numerous satisfied clients worldwide.

>>> Read more: What Types of Materials Can Precision CNC Machining Work With?

Assessing Turnaround Times

Lead times play a vital role in the decision-making process when selecting precision machining services.

Your primary concern is to ascertain whether a manufacturing partner can efficiently machine and deliver your product within the specified timeframe.

Reputable machine shops typically disclose their standard turnaround times, which may vary depending on the size and complexity of your manufacturing project.

Presently, some of the most innovative precision machining companies utilize automated quoting software to estimate production costs and processing times for orders. This software considers factors such as ongoing tasks, equipment availability, and more, streamlining the purchasing process for clients and providing a comprehensive understanding of the production timeline.

Moreover, it’s essential to ensure that your precision machining shop offers swift, traceable shipping options for your finished products.

With MATEC VN, we always measure production time and ensure on-time delivery to customers.

Considering Communication

In the past, finding a manufacturing service partner involved searching through phonebooks, making numerous calls, and gathering price quotes.

Moreover, navigating the language barrier was another challenge when dealing with global precision manufacturing firms.

This process often consumed a significant amount of time in search of the right partner. However, thanks to advancements in computer technology, communication is now more accessible than ever.

Today, you can request bids from 20 quick prototyping services in less than an hour, if necessary, all through the convenience of the internet.

Despite the ease of online communication, evaluating how effectively a machining service communicates remains crucial.

A manufacturing service that promptly responds to your calls or emails and makes themselves available to address any inquiries or concerns demonstrates a positive indicator of their reliability.

Effective communication between customers and manufacturing service providers is paramount.

It not only facilitates the successful completion of your production project but also fosters ongoing collaboration opportunities. All customers of MATEC VIETNAM are very satisfied with our services and are always ready to cooperate again.

Assessing Pricing and Budget Compatibility

There are numerous companies offering precision CNC machining services, each with varying pricing structures.

The size and quality of the machinery are the primary factors influencing precision machining costs. It’s important to find a provider that aligns with your budgetary constraints.

However, exercise caution when considering precision CNC machining services offered at discounted rates, as they may compromise long-term functionality.

Providers offering significantly lower prices may employ inexperienced staff and deliver subpar service quality.

Conversely, refrain from hastily agreeing to services from companies with excessively high pricing. Some may inflate their prices to attract customers, without necessarily offering superior quality.

Therefore, it’s advisable to seek out a shop that offers competitively priced precision machining services, ensuring a balance between affordability and quality. At MATEC VIETNAM, we are based in Vietnam, where labor and raw material costs are low. As a result, we offer relatively low production costs compared to many other manufacturers worldwide

Conclusion

When considering a CNC machining service provider, several key factors should be taken into account. First and foremost, it is essential to assess the provider’s capabilities, including their equipment, expertise, and capacity to meet your specific needs.

Additionally, evaluating the provider’s quality control measures, delivery reliability, and customer service responsiveness is crucial to ensuring a successful partnership.

Furthermore, cost-effectiveness and the ability to offer competitive pricing without compromising quality should also be carefully considered.

By thoroughly evaluating these considerations, businesses can make informed decisions and select a CNC machining service provider that best aligns with their requirements and goals, ultimately leading to enhanced efficiency, productivity, and overall satisfaction.