Nowadays, more and more people are using motorcycles for transportation. Both gasoline and electric engines are popular among users. Consequently, the demand for motorcycle parts is increasing. Manufacturers need parts to produce motorcycles, and customers need parts to replace broken ones.

The production of motorcycle parts is a complex process, and methods such as CNC machining and Swiss turning are widely adopted by many motorcycle parts manufacturers, including MaTec Vietnam. In this article, we will explore how motorcycle parts are made and the role CNC machining plays in their production.

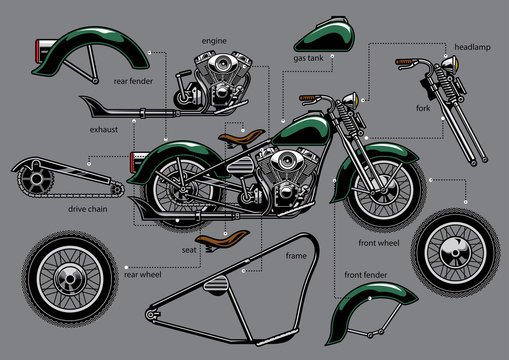

Overview of Motorcycle Parts

Motorcycles are complex machines made up of numerous components that work together to ensure performance, safety, and reliability. Understanding the different types of motorcycle parts and their roles is crucial for appreciating the intricacies of motorcycle design and maintenance.

Types of Motorcycle Parts

Engine Components

- Cylinder Heads: These house the engine’s intake and exhaust valves.

- Pistons: Move up and down inside the cylinder, creating the necessary force to drive the motorcycle.

- Crankshaft: Converts the linear motion of the pistons into rotational motion to turn the wheels.

- Camshaft: Regulates the intake and exhaust valves’ timing

Transmission Parts:

- Gearbox: Contains gears that adjust the motorcycle’s speed and torque.

- Clutch: Engages and disengages the power from the engine to the gearbox.

- Drive Chain/Belt: Transfers power from the gearbox to the rear wheel.

Body Parts

- Frame: The skeleton of the motorcycle, providing structure and supporting all other components.

- Fuel Tank: Keeps the gasoline that the engine needs stored.

- Fairings: Aerodynamic covers that reduce air resistance and protect the rider from wind.

- Seat: Provides somewhere to sit for the rider.

Electrical Components

- Battery: Powers the electrical systems when the engine is off or at low RPM.

- Ignition System: Starts the engine and controls the spark that ignites the fuel-air mixture.

- Lighting System: Includes headlights, tail lights, and indicators for visibility and safety.

Suspension Parts

- Forks: Connect the front wheel to the frame and absorb shocks from the road.

- Shock Absorbers: Located at the rear, these also absorb road shocks to provide a smoother ride.

Importance of High-Quality Parts for Motorcycle Performance and Safety

High-quality motorcycle parts are essential for several reasons:

- Performance: Premium parts ensure optimal functioning of the motorcycle, resulting in better speed, handling, and fuel efficiency.

- Safety: Reliable components reduce the risk of mechanical failure, which can be crucial for preventing accidents.

- Durability: High-quality parts are more resistant to wear and tear, reducing the need for frequent replacements and maintenance.

- Compliance: High-quality parts often meet or exceed industry standards and regulations, ensuring that the motorcycle is roadworthy and legally compliant.

Common Materials Used in Motorcycle Parts Manufacturing

Steel

- Often utilized because of its robustness and longevity.

- Commonly found in the frame, engine components, and drive chains.

Aluminum

- Lightweight and resistant to corrosion.

- Used in engine components, wheels, and some body parts to reduce overall weight and improve fuel efficiency.

Plastics

- Economical and lightweight.

- Used for body panels, fairings, and certain internal components where high strength is not as critical.

Carbon Fiber

- Robust and Lightweight.

- Used in high-performance motorcycles, particularly in body panels and some structural parts.

Rubber

- Used for tires, seals, and gaskets.

- Provides necessary grip and flexibility.

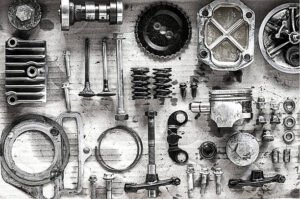

The Manufacturing Process of Motorcycle Parts by CNC Machining

CNC machining is a pivotal technology in the production of high-precision motorcycle parts. This process ensures that parts are manufactured to exact specifications, resulting in high-quality components that enhance the performance and safety of motorcycles.

Here is a detailed description of the general steps involved in producing motorcycle parts through CNC machining:

Design and Prototyping

- Conceptual Design: Engineers and designers start with the conceptual design of the motorcycle part, considering factors such as functionality, integration with other parts, and performance requirements.

- CAD Modeling: The design is translated into a detailed 3D CAD (Computer-Aided Design) model. This model serves as a blueprint for the part, specifying dimensions, shapes, and tolerances.

- Simulation and Analysis: Using CAE (Computer-Aided Engineering) tools, the design is simulated to analyze stress, thermal, and dynamic behaviors. This step helps in identifying potential issues before physical prototyping.

- Prototyping: A physical prototype is created, often using 3D printing or initial CNC machining. This prototype is tested for fit, form, and function, allowing for design adjustments before full-scale production.

Material Selection

- Material Requirements: The selection of materials is based on the part’s requirements, such as strength, weight, heat resistance, and corrosion resistance.

- Common Materials: Commonly used materials include steel for strength, aluminum for lightweight components, and various plastics for non-structural parts. High-performance parts may use advanced materials like carbon fiber composites.

- Material Procurement: Once selected, the materials are sourced from suppliers, ensuring they meet the required quality standards and specifications.

Manufacturing

- CNC Programming: The CAD model is converted into a CNC program using CAM (Computer-Aided Manufacturing) software. This program contains the instructions for the CNC machine to follow, including tool paths, cutting speeds, and feed rates.

- Setup: The proper fixtures and tooling are installed on the CNC machine.The raw material is firmly fixed in position.

- Machining Process: The CNC machine precisely cuts, drills, mills, or turns the material into the desired shape. Depending on the complexity of the part, multiple CNC processes may be used.

CNC Milling: Used for creating complex shapes and features such as slots, holes, and contours.

CNC Turning: Used for producing cylindrical parts such as shafts and bolts.

CNC Drilling: Used for creating precise holes in the parts.

- Finishing Operations: Post-machining processes like deburring, polishing, and coating are applied to achieve the final surface finish and meet aesthetic and functional requirements.

Quality Control and Testing

- Inspection: Each part undergoes rigorous inspection using precision measuring tools and instruments such as calipers, micrometers, and CMMs (Coordinate Measuring Machines) to ensure it meets the specified dimensions and tolerances.

- Functional Testing: Parts are tested for functionality under simulated operating conditions. For example, engine components may be subjected to thermal and stress tests to ensure they can withstand real-world conditions.

- Compliance Checks: Parts are checked for compliance with industry standards and regulations, ensuring they are safe and reliable for use in motorcycles.

- Batch Testing: In production runs, sample parts from each batch are tested to ensure consistent quality across the entire production.

CNC Machining in Motorcycle Parts Production

CNC machining is integral to the production of high-precision motorcycle parts. This advanced manufacturing technology enables the creation of complex and highly accurate components, essential for the performance, safety, and reliability of motorcycles.

Specific Motorcycle Parts Commonly Produced Using CNC Machining

Engine Components

- Cylinder Heads: CNC machining ensures precise control over the complex geometry of cylinder heads, improving combustion efficiency and performance.

- Pistons: CNC machines can produce pistons with exact dimensions and surface finishes, essential for minimizing friction and wear.

- Crankshafts: Precision machining of crankshafts ensures smooth engine operation and durability.

Brake Systems

- Brake Discs: CNC machining allows for the production of brake discs with precise dimensions and surface finishes, essential for effective braking performance.

- Brake Calipers: These components require precise machining to ensure proper fit and function in the braking system.

Suspension Parts

- Fork Tubes: CNC machining produces fork tubes with the precise dimensions necessary for smooth operation and effective shock absorption.

- Shock Absorber Components: Parts such as pistons and rods are machined to exact specifications to ensure the suspension system functions correctly.

Examples of CNC Machining Processes Used in Motorcycle Parts Manufacturing

CNC Milling

- Process: CNC milling involves the use of rotating cutting tools to remove material from a workpiece, creating complex shapes and features.

- Applications: Commonly used for producing engine blocks, transmission cases, and various brackets and mounts. The precision of CNC milling is crucial for parts requiring detailed contours and tight tolerances.

CNC Turning:

- Process: CNC turning involves rotating the workpiece while a cutting tool moves along its axis to create cylindrical parts.

- Applications: Ideal for producing parts like axles, drive shafts, and bolts. CNC turning ensures these parts are perfectly round and meet exact specifications for diameter and length.

Swiss Turning

- Process: Swiss turning is a specialized form of CNC turning where the workpiece moves axially through a guide bushing while the cutting tool remains stationary. This process is known for its ability to produce small, precise parts with excellent surface finishes.

- Applications: Commonly used for producing small components such as screws, pins, and bushings, which require high precision and fine details.

Benefits of CNC Machining for Motorcycle Parts Manufacturers

Improved Product Quality

- Precision and Accuracy: CNC machines can produce parts with extremely tight tolerances and intricate details, ensuring high-quality components that perform reliably.

- Consistency: CNC machining ensures that each part is manufactured to the same exact specifications, reducing variations and improving overall product quality.

Reduced Production Time

- Efficiency: CNC machines can operate continuously with minimal supervision, significantly speeding up the manufacturing process.

- Automation: Advanced CNC systems can automate multiple stages of production, from material handling to finishing operations, further reducing production time.

Cost-Effectiveness in Large-Scale Production

- Reduced Waste: CNC machining is highly efficient, minimizing material waste and reducing overall production costs.

- Scalability: Once a CNC program is developed, it can be used to produce large quantities of parts with minimal additional setup, making it cost-effective for large-scale production runs.

- Lower Labor Costs: The automation of CNC machining reduces the need for manual labor, cutting down on labor costs and increasing production efficiency.

MaTec Vietnam – Best Manufacturer of Motorcycle Parts for You

MaTec Vietnam has established itself as a leading manufacturer in the motorcycle parts industry, renowned for its commitment to quality and innovation. With over 10 years of experience, MaTec Vietnam has become a trusted partner for clients around the globe, including the USA, Germany, Canada, Australia, and Japan.

The company’s success is underpinned by its dedicated team of 50 engineers and a fleet of 30 advanced CNC machines, enabling it to deliver high-precision components that meet the stringent requirements of the motorcycle industry. We always strive to provide our customers with the best services and the most optimal customer care policies. Therefore, please contact us now to receive the best advice and quotations.

Conclusion

Motorcycle parts are essential components in our daily activities. The increasing demand for motorcycles also drives the need for parts production. Recognizing this, MaTec Vietnam has made significant investments in infrastructure and human resources to become the leading component manufacturer in Vietnam.

Therefore, please send us the information and drawings of the components you require so that we can advise you and become your partner in the future.